The Process: Not your average detail...

Let me start off by saying welcome! I wanted to create my first post into an educational one and show what the process looks like when you select us to correct and protect your vehicle. Our process is one of which takes a lot of time with packages ranging from 8 hours to 40 hours. As we dive into our post we show a summarized glimpse of what it actually takes to bring your pride and joy into a show quality finish. Are there business' out there that can do a wash and buff in 1 hour? Absolutely, but that isn't us.... Enjoy!

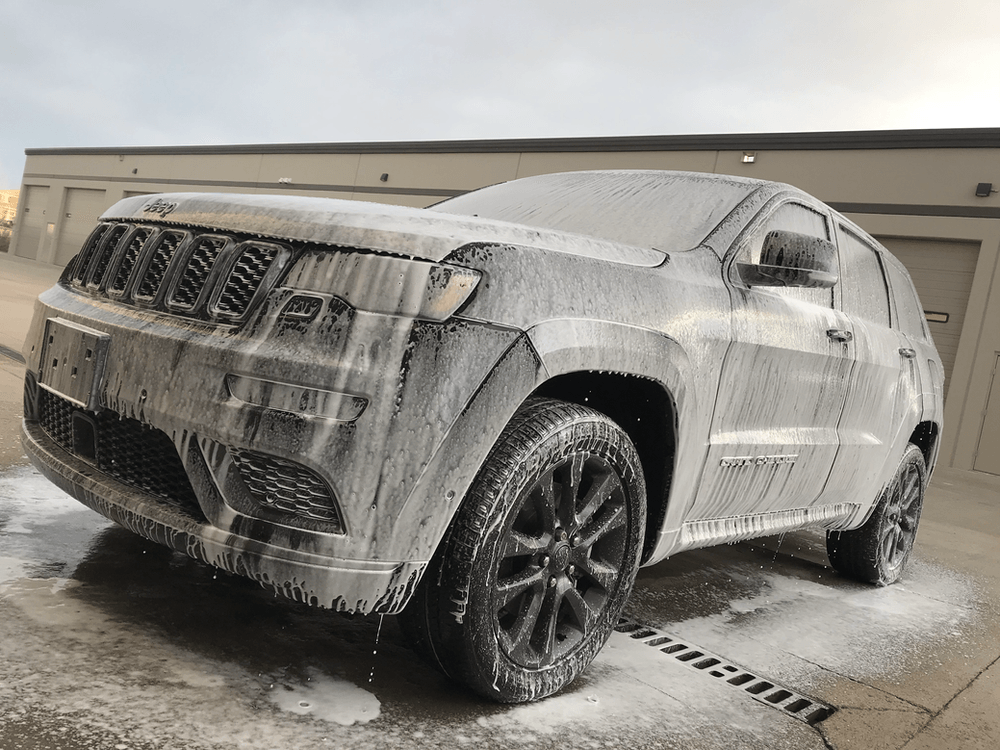

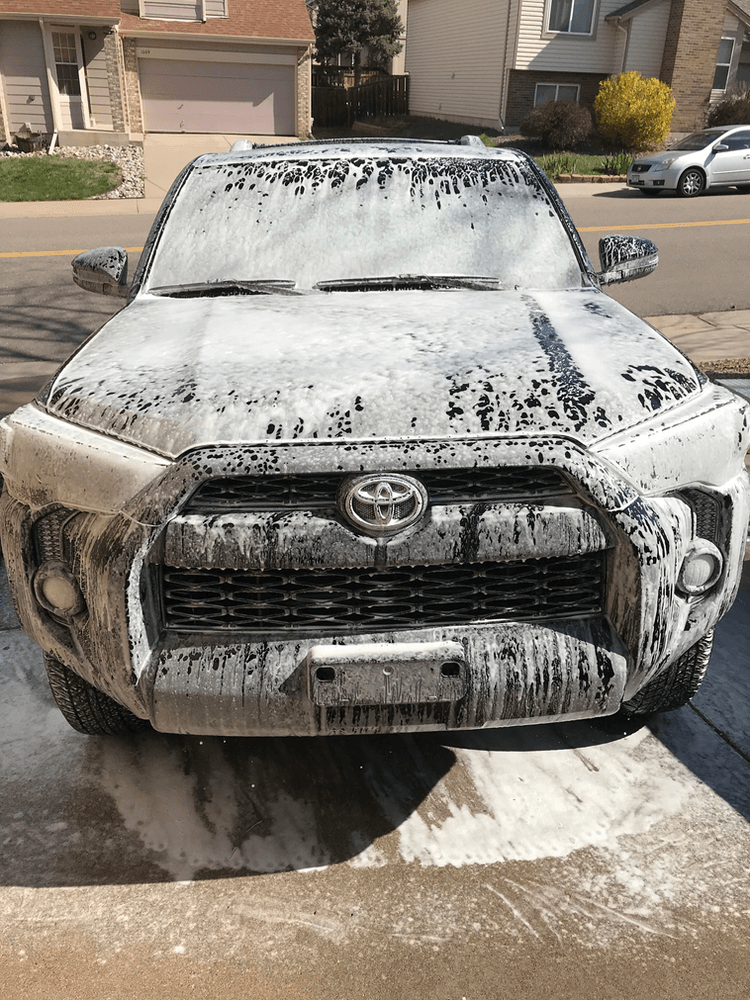

We start off with a full paint decontamination. This process is a multi step process and starts out with a foam bath.

Soap used: #shinesupply HotShot Soap

After we allow the foam to pick up as much loose dirt as possible we then spray all surfaces with Gyeon Iron. Gyeon Iron works exactly how it sounds - it reacts with the iron particles that are embedded in the paint and allows us to safely wash them off. After allowing ample time for the product to react we then rinse it off and wash all surfaces with a proper 2 bucket method wash. Even if we are correcting the paint we always use proper wash methods. We don't want to induce any extra scratches that we have to correct later on.

After the vehicle is washed we bring is inside and completely dry the vehicle using compressed air and our Gyeon Silk Dryer. We then continue the decontamination process with using a clay bar or a synthetic clay pad. We chose a clay bar for this 4Runner as we found the paint to be very soft. The clay bar gave us more control around edges and moldings.

Claybar used: #gyeonquartz_us with #Shinesupply clay lube

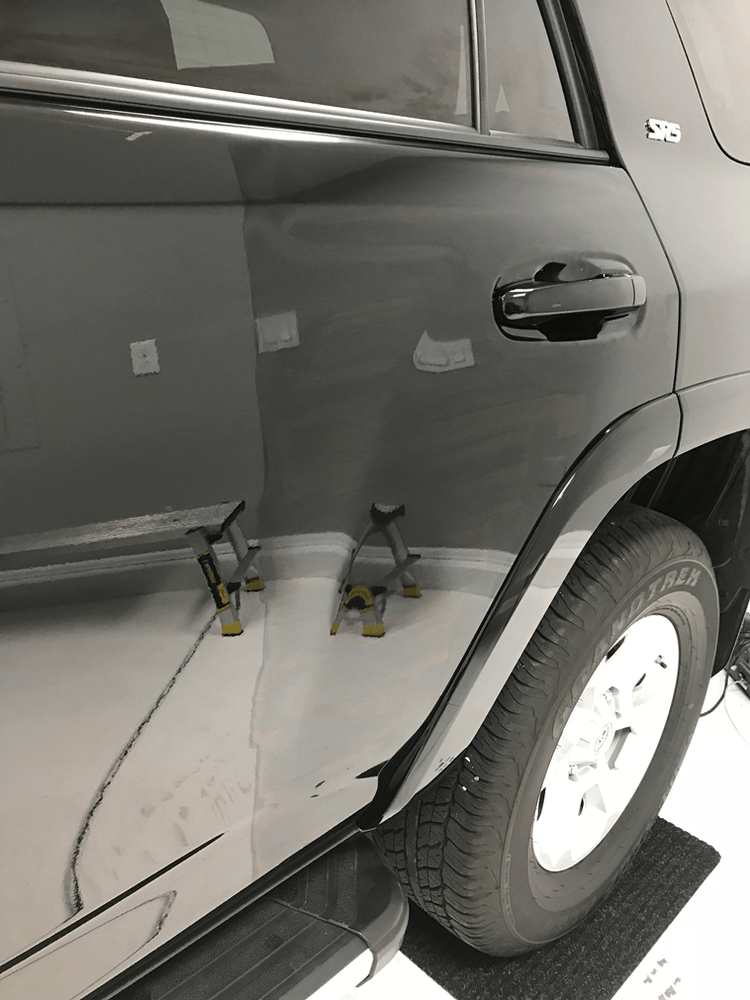

After we have finished with the clay bar we then do a complete wipe down with Gyeon Prep. This allows us to completely remove any oils and residue and allows us to see the actual condition of the paint. Now, this 4Runner was purchased brand new and came with a lot of marring that most likely was induced from maintenance washes at the car lot.

#gyeonquartz_us Prep with soft wipe towel

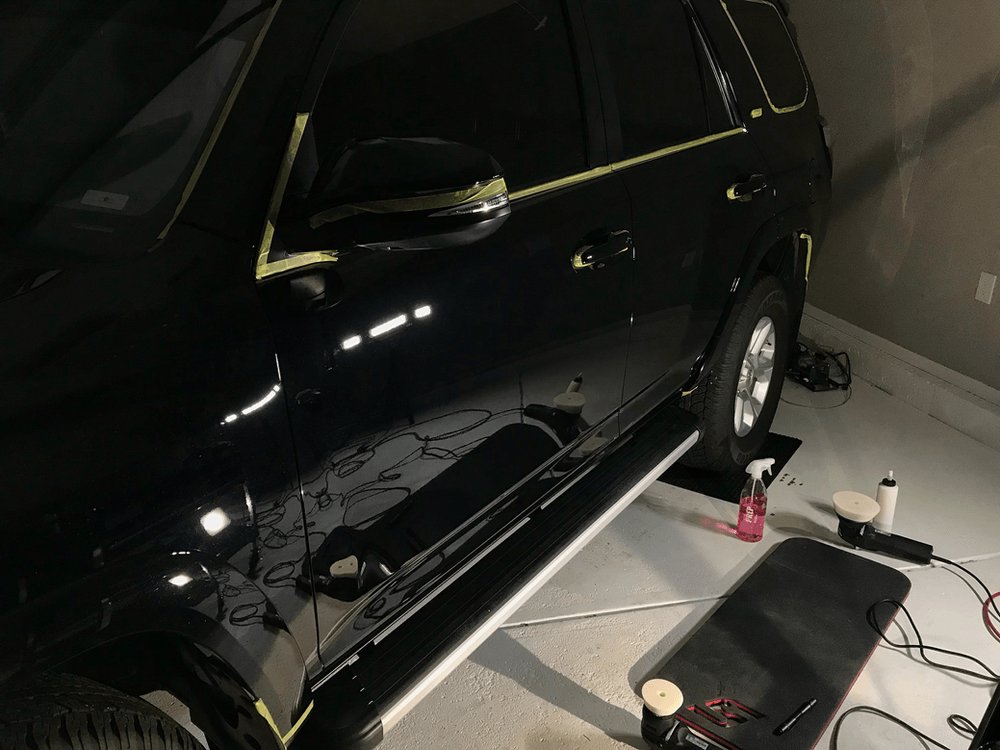

Once we have the paint fully decontaminated and prepped we will then go around and tape off any sharp edges, trim, badges and important pieces that we want to protect.

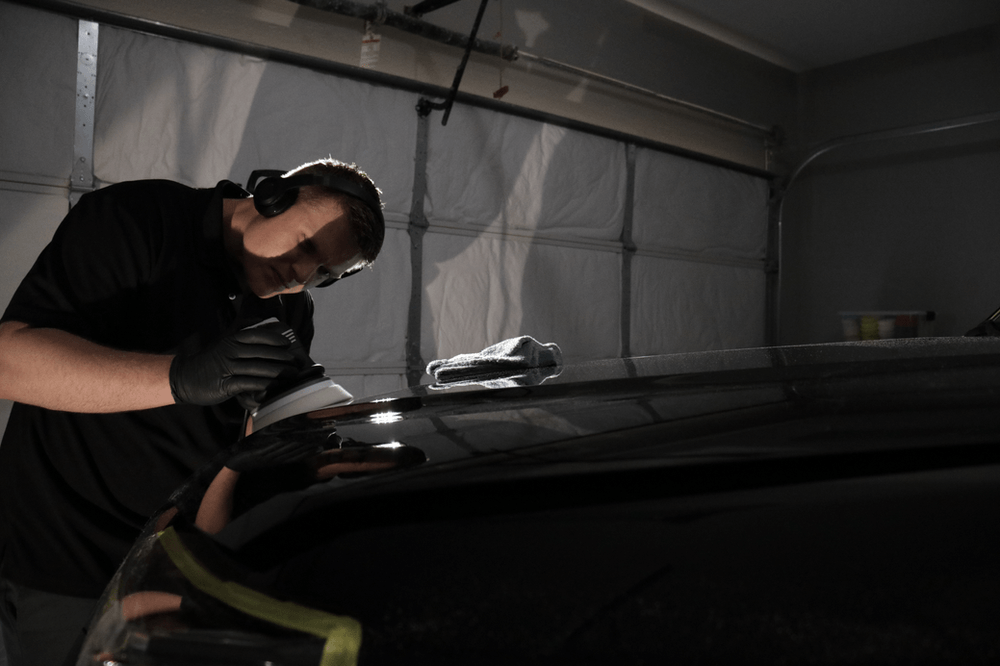

We have found out over the years that not all paints are created equal and because of this we start off every correction with a few test spots. By changing our machine, pressure, pad and/or polishing compound we are able to create the desired finish. After a few test passes we were ready to go!

Machine and pads used: #Rupes duetto with white finishing pad

Once we have corrected every painted panel to the desired level; we then do another complete wipe down with Gyeon Prep. This final wipe down allows us to ensure all compounding and polishing chemicals are removed from the painted surface. This gives us the best bond to the paint when we go to apply our coating. Depending on the severity of defects and dust that is collected from the paint correction process we may just go ahead and wash the vehicle one more time. In this case we were just polishing which gave us minimal dust and was taken care of with a little compressed air.

Now we can begin the coating process! Depending on which level and product that is chosen; this process can range from one step to 3 or 4 steps. We chose to go with our Level 2 coating Gyeon Syncro. It is a new product that was released during Sema 2017 and is considered one of the highest level coatings available to non certified detailers in the Gyeon Quartz line.

Coating used: #Gyeonquartz_us Syncro kit

Gyeon Syncro consists of 2-3 layers of there tried and true Q2 Mohs followed by 1 layer of the topcoat. In this case it is Q2 Skin. The top coat gives it that final layer of gloss and hydrophobic characteristic. We apply the coating in sections allowing the product to flash and then be wiped off.

After each layer is applied we then cure each panel with an IR curing lamp for 10-15 minutes. This gives us added durability, gloss, and speeds up our curing time.

We then went around with one more layer oh Mohs base coat and cured that layer followed one complete layer of Q2 Skin.

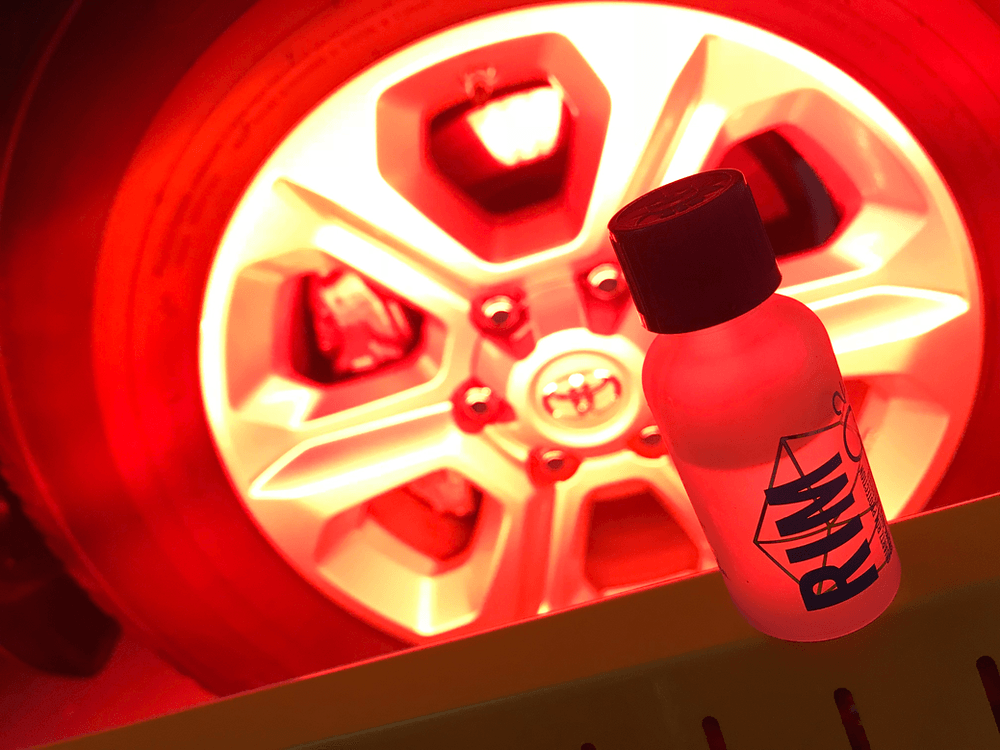

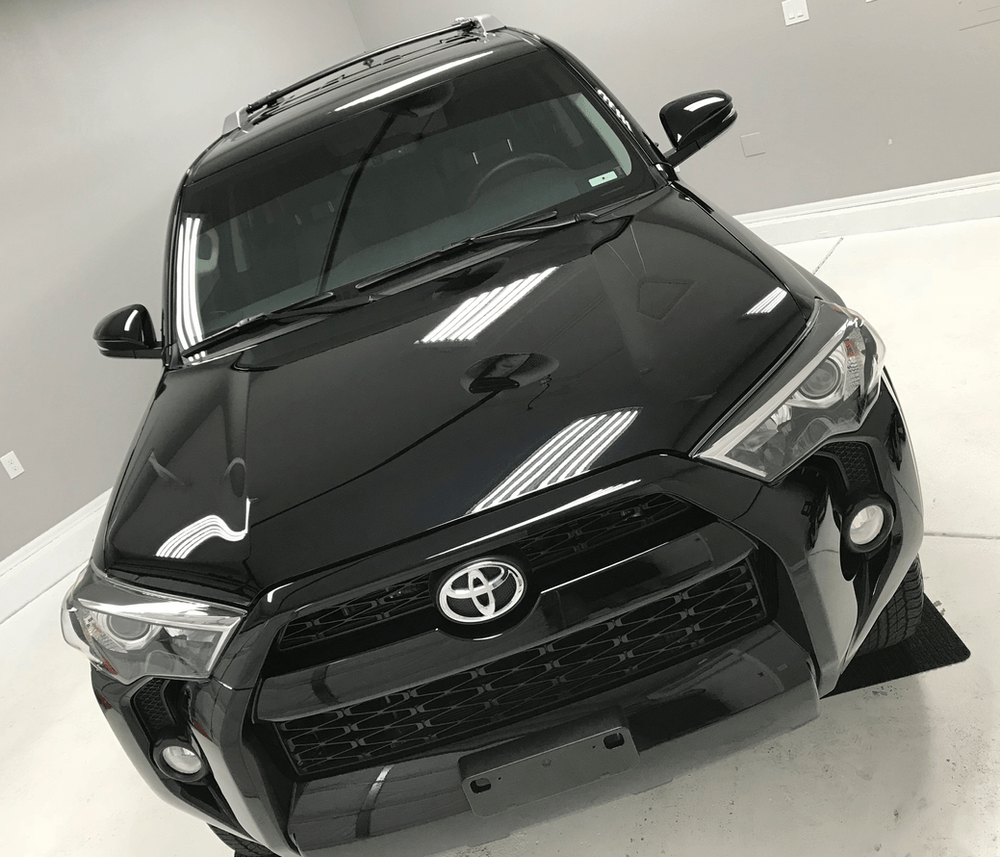

Our final thoughts: very excited how this Toyota 4Runner turned out. It is a midnight black paint scheme which has a flake built into it that shows a blue/ silver speck when in direct sunlight. Our Gyeon coating system left this paint protected from all the Denver elements for years to come! We finished off the vehicle with coating the trim and windshield with Gyeon Products. We opted to only coat the wheel faces on this vehicle. Our level 2 coating system normally comes with our wheels off coating service.

Here are some final photos from the project! After hours of polishing it has left the finish with a deep reflection. While the coating adds great gloss to a finish, it is best to coat over an already polishes clear coat.

Thank you for viewing; check back for future projects!